Custom Parts Machining, Driven by Certifications and Continuous Improvement

High-quality, dependable custom parts machining requires consistency and compliance. As a veteran-owned business and ITAR-registered manufacturer, Whitmer Industries is committed to maintaining the highest standards of quality and security in every project we complete. Our certifications reflect our dedication to both technical excellence and regulatory responsibility.

Our recent completion of the CMMC Level 1 self-assessment marks an important milestone on our path toward full CMMC Level 2 certification, which we plan to achieve in the spring of 2026. This step positions us as a forward-thinking Pittsburgh machine shop that’s always ready to meet the stringent demands of our defense and aerospace customers.

What ITAR Registration Means for Our Customers

Achieving ITAR registration in September 2025 was a key part of our strategy to support customers in defense, aerospace, and other high-security industries. Being an ITAR machine shop means we have the systems and safeguards in place to protect sensitive technical data and ensure compliance with U.S. export regulations.

For our customers, ITAR registration translates into confidence that their proprietary information and parts will be handled securely, and that every process at Whitmer Industries meets government and industry standards. This opens the door for us to take on more defense and aerospace machining work while maintaining our commitment to precision and reliability.

CMMC Compliance: Preparing for the Future

Our successful CMMC Level 1 self-assessment and ongoing journey toward CMMC Level 2 certification highlight our proactive approach to continuous improvement. Many shops are just beginning to think about compliance, but our president, Dave Whitmer, brings deep experience in regulated environments. Having spent 24 years working for the federal government and additional time in the financial sector managing SOC 2 audits (a process quite similar to CMMC and AS9100!), Dave understands that the key to long-term success involves building compliant systems early.

By implementing the right digital infrastructure from the start, we’ve avoided the “unlearning” process that many legacy manufacturers will face later. This mindset supports our own growth and ensures that our customers benefit from a more efficient, secure, and reliable partner.

Investing in Advanced Technology

As part of our CMMC readiness and overall improvement plan, we’ve transitioned to Mastercam, a software platform that aligns with compliance requirements and supports our custom parts machining services. This upgrade ensures tighter data control, improved traceability, and seamless integration with our digital systems.

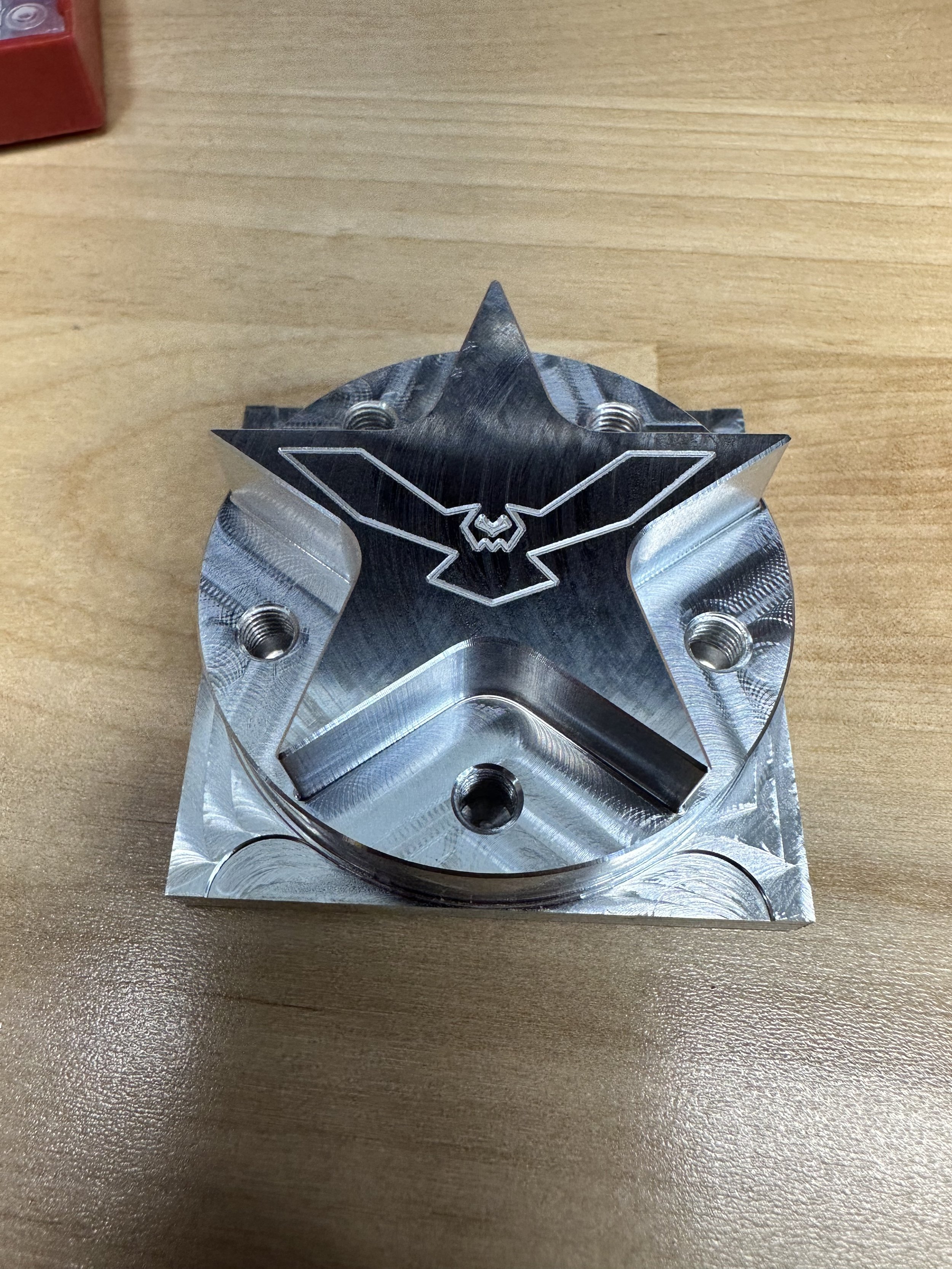

Additionally, Whitmer Industries has also invested in a Zero Point system from Fifth Axis, which enhances setup speed and repeatability. This system enables our team to use our cobot to manage tool changes and part swaps automatically. The result is the creation of an efficient cell capable of handling low-volume, high-mix jobs with the same speed and precision as high-volume, low-mix runs.

Precision You Can Count On

From rapid prototyping to full production, our team prioritizes quality and precision in everything we do. By pairing cutting-edge technology with a culture of continuous improvement and pursuit of industry-specific certifications, Whitmer Industries delivers results that exceed our customers’ expectations.

Are you ready to partner with an expert in custom parts machining? Request a quote from Whitmer Industries!