How Whitmer Industries Supports Fast, Flexible Rapid Prototyping

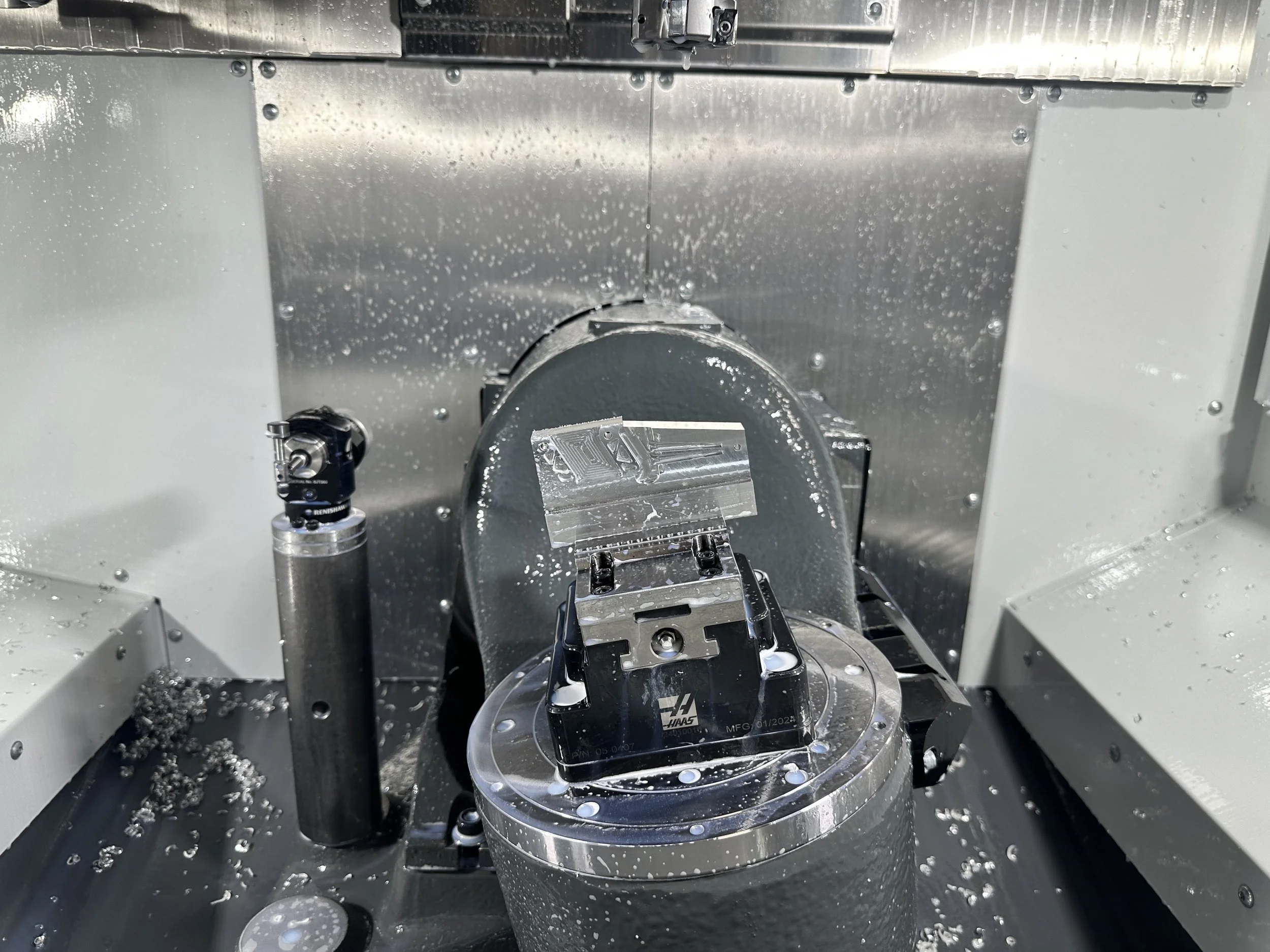

Whitmer Industries is built for speed and adaptability. That extends to our approach to rapid prototyping. Combining deep engineering expertise, advanced automation, positive vendor relationships, and a customer-first mindset, our teams move projects from concept to finished part with impressive efficiency.

In our prototype machining services, we streamline every step of the process to ensure your prototype is manufacturable and functional in its required application. Here’s how we accomplish this:

What Rapid Prototyping Looks Like at Whitmer Industries

We start with whatever you have, whether it’s a CAD model, blueprint, or broken part.

Our rapid prototyping workflow is designed to meet you where you are. Customers come to Whitmer Industries with everything from:

A complete CAD model

A full engineering drawing

A blueprint-only drawing

A broken part that needs to be reverse-engineered

If you have a damaged component and can’t procure a replacement, our team can reverse engineer the part directly. Ideally, we prefer the physical part, but if shipping isn’t feasible, detailed photos with scale references (such as rulers) can guide us. From there, we often begin with a 3D-printed base model to confirm fit and function before machining the final version.

Have requests or requirements? Send them to us!

The more information you can share, the stronger and faster the outcome. Helpful details include:

Hole requirements (tapped holes, thread specs, through holes, tight or standard fits, and so on)

Edge preferences (chamfers vs. minimal break)

Surface finish requirements

Functional needs such as sealing, vacuum compatibility, or cosmetic importance

When in doubt, send as many details as possible. More context for our team means more transparency into precisely what you need and, therefore, better results for your prototypes.

Why Whitmer Industries Excels at Rapid Prototyping

Exceptionally fast turnarounds

We’re able to deliver true quick-turn machining because our workflow is intentionally built for speed:

Machining automation handles long production runs

Human capacity is reserved for complex prototype programming and setup

Our team routinely works nights and weekends when needed

Engineers and machinists are cross-trained, making us nimble and responsive

This combination gives you a major advantage when timelines are tight.

Smart use of technology, including AI

We embrace tools that improve efficiency without sacrificing quality. This includes:

AI-assisted toolpath programming

AI-supported administrative workflows

Early testing of voice-integrated systems for ERP and KPI tracking

Software and processes aligned with CMMC Level 1 requirements

In short, technology helps us reduce bottlenecks so our team can focus on the high-value activities that go into making great parts.

Engineering expertise, built into every step

Unlike many shops, Whitmer Industries isn’t “machining-only.” With engineering talent on our team, we support customers with Design for Manufacturing (DFM) guidance, ensuring prototypes are both functional and economical.

If a file contains inconsistencies or unclear features, we don’t cut the part as-is; we ask questions and confirm intent. This often prevents costly redesigns later.

We also work closely with customers planning higher production volumes. If your long-term goal is 1,000 parts but you’re only ordering 10 prototypes, that completely changes how we approach tooling, fixturing, machining, and finishing. Early collaboration helps reduce costs and streamline future production.

Immediate access to materials

With a primary material supplier just 1.5 miles away, we can source most materials same-day, and even on weekends when necessary. This helps us keep prototype timelines short and predictable.

A Partner You Can Trust for Prototype Machining

As an ITAR machine shop with experience in industries like aerospace, defense, robotics, and medical machining, Whitmer Industries understands the importance of accuracy and confidentiality. Our rapid prototyping services are rooted in clear communication and deep technical expertise.

When you need a prototype made quickly and made right, our team is here to support you from the first sketch to the final part. Request a quote from Whitmer Industries to get started.